LNG TANKS

Advantages

TENSA technologies applied in LNG tanks are aimed to:

- Strengthen and confine the external concrete structure, to increase concrete performance and structure robustness under liquid containment actions (post tensioning): such action may be done under cold temperature status (cryogenic conditions)

- Protect structures from the seismic action or, in general, from dynamic actions (i.e. wind)

- Consolidate and strengthen ground beneath the structure (ground anchors)

The technology of ground anchoring is widely used especially as far as foundation consolidation and retaining walls are adopted.

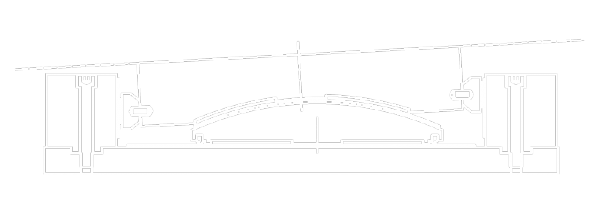

At the connection between basement and walls it is possible to use:

Structures, indeed, undergo displacements, rotations and deformations caused by acting loads (of static, dynamic, thermic nature etc.) or by phenomena such as shrinkage and creep, linked to the maturation of materials.

Movements, rotations and deformations need to be allowed for and contemplated where strictly necessary and in accordance with the designer’s constraining system.

Base seismic isolation represents an important tool in the hands of the designers to protect the structural and non-structural components of a construction.

The isolators limit the acceleration transferred to the structure and reduce inertial stress by increasing the oscillation period.

Dampers are hydraulic devices depending on load application velocity and are able to dissipate part of the dynamic energy entering into the structure.

STUs are hydraulic devices, able to create, only for impulsive external force, a temporary rigid connection between two parts of the structure.

Concrete walls are usually post tensioned, designing structures as reinforced shells.

Post tensioning plays a key role with vertical or annular (looped shape) tendons, creating a deep net of compression forces to the structure.

Depending on the different design choices for structure thermal insulation, tendons may be required to perform in low temperature conditions (cryogenic), especially in extreme events (failure, accidents).

In such cases tendons need to be suitable to meet International Standards (ETAG013, EN14620-3, FIP SR 88/2) for cryogenic working conditions.

TENSA MTAI system has been positively tested to assess compliance to requirements set in standards above.

Tanks top roof may be post tensioned depending on design choices.

Usually cryogenic conditions are not applied to this part of the structure.